WhyVertical

Till Injector?

LEARN MORE

- PARTS COVERAGE

- BUILT TO PERFORM

- CUSTOMIZE & BUILD

- COMPETITIVE PRICING

PROUDLY MADE IN

THE USA

Learn why to buy american made

Benefits Of Buying Products Made In The USA

You may be wondering: what are the true

benefits of buying goods that are made in

america, and what kind of impact does it truly

have on us here?

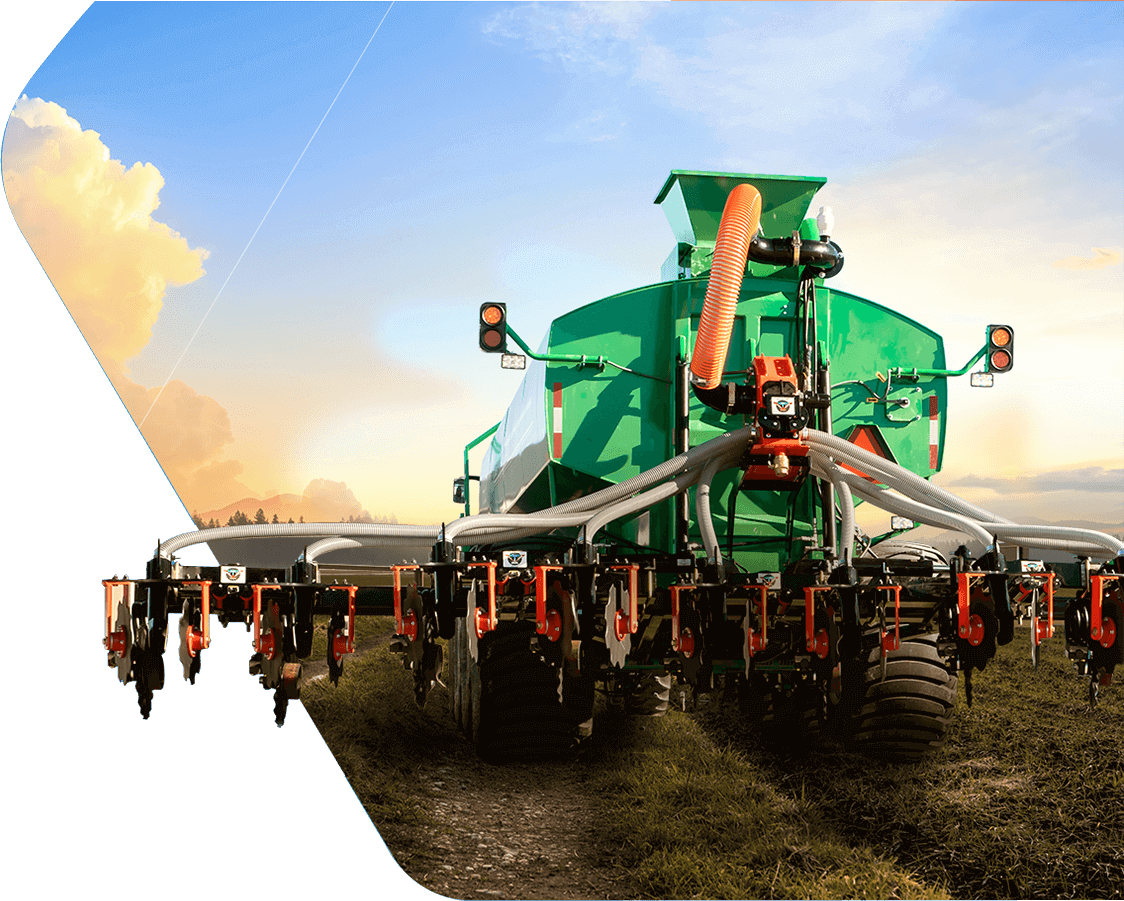

Manure

management

made simple

The Most Durable & Simplest Design

You Will Find.

The Lowest Maintenance, Manure

Injection System On the Market

Today.

360º

drag to rotate

-

High Speed

3-10 MPH with excellent performance

-

High Residue

Heavy corn stalks without clogging

-

Low Draft Manure Injection

Up to 50% less draft than prior technology & Up to 15,000 gal per acre

- Injects manure up to 7” below surface

- Variety of Blades to match your needs; No Till to Conventional Till

- 3.5” ID Manure Pipe with 2.5" Hose

- Adaptable to different bar sizes & drag hose systems

- Other Blades Available for Different Soil Types

- Industry Leading Maintenance Free Closing System

- Hi-Flow Impellers for Hi-Speed Application

Great Equipment Yet Environmentally Friendly!

For me, the VTI provides the flexibility to apply manure under a wide variety of conditions and in any type of crop residue. As a no-tiller, I want to do that in a way that is fast, economical and fits into our no-till system

Phil Reed (Founder & Inventor of VTI)

VTI has been approved and designated by the Iowa Department of Natural Resources as a true no-till liquid manure injector. Our manure injection systems do not leave any manure exposed on the soil surface.

Since the manure is covered, ammonia losses due to volatility are reduced significantly, as is the negative environmental impact from runoff. That’s even more important to no-tillers who apply liquid manure, since ammonia losses can increase when manure is applied on top of crop residue.